Surfaces Treatment

NANOTECNOLOGIA PRONORTEC

PRONORTEC nanotechnology is a new and innovative chemical process for the metal surface treatment, based on the use of organic Phosphorus compounds.

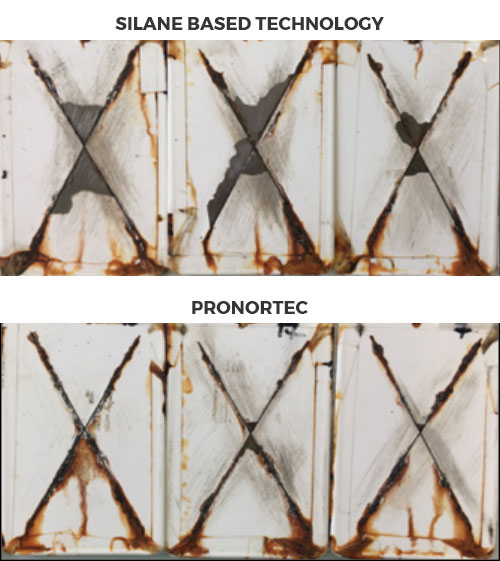

The nanocoating created by the PRONORTEC process is highly hydrophobic, nanometric, and it guarantees excellent adhesions and a high corrosion resistance degree, compared with other nanotechnology pre-treatment methods available on the market.

PRONORTEC is a multi-metal product (iron, aluminum and galvanized steel). It is a one-component process and t is not necessary to add any additive to correct pH, nor any concentration of other metals. This process is highly revolutionary both for its ease of use and for the quality of results.

PRONORTEC process is stable for at least 6-12 months and it does not create any kind of sludge. It can be applied by spraying, immersion, or nebulization.